Item 1: Waterjet cutting dedicated chiller

Model | WW-5P (others available) |

Voltage | 380V |

Power | 14kw |

Cooling capacity | 12500Kcal/H |

Refrigerant | Freon R22 / Refrigerant R41 |

Water tank capacity | 80L |

Flow-rate | 120L/min |

Discharge head | 18m |

1. WIN-WIN's chiller is specifically designed for waterjet cutting equipment and differs from ordinary chillers on the market.

2. This chiller effectively reduces oil temperature, as well as the overall temperature of the intensifier and the cutting head. This significantly increases the lifespan of the intensifier's high-pressure seal, reducing seal failure caused by thermal expansion and contraction, and ensuring more stable intensifier pump operation.

3. Features include automatic start/stop, constant temperature setting, English interface, microcomputer control system, and more precise temperature control.

4. The connection between the chiller and intensifier pump uses a modular design with quick-connect circuitry for convenience and speed.

Item 2: Waterjet Filtration System / Water Softening System

Model | WW-1T |

Voltage | 220V |

Water purification flow-rate | 1000L/H |

Filtration accuracy | 0.0001

micrometer |

Filtered water quality | Purified water/Direct drinking water |

1. Equipped with a Water Softening System, it effectively filters particulate matter, rust, bacteria, suspended solids, etc., from the water. Eliminating these substances effectively extends the orifice's lifespan and reduces the impact of impurities in the water.

2. The Water Softening System removes chlorine, heavy metals, colloids, and other substances from the water, effectively softening the water. This reduces wear and tear on dynamic seals and metal seal surfaces, extending the lifespan of high-pressure components in the intensifier and ensuring more stable equipment operation.

3. A five-stage filtration system using quartz sand, granular activated carbon, resin, PP cotton, and an RO reverse osmosis membrane ensures the filtered water meets direct drinking water standards.

4. A microcomputer control display screen makes operation convenient.

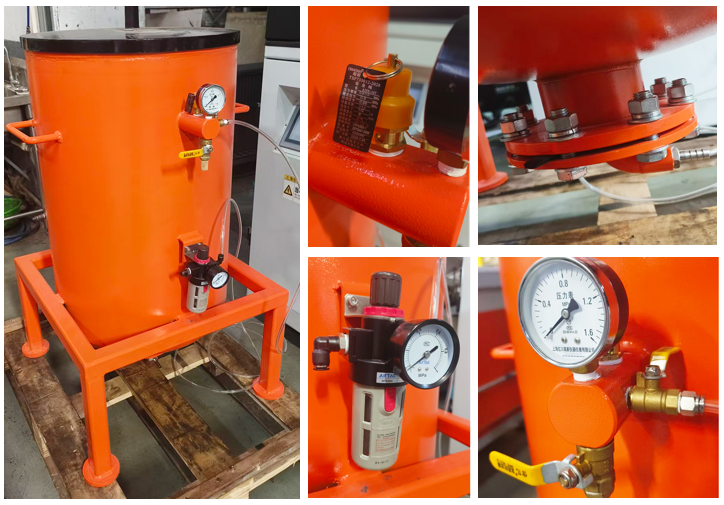

Item 3: Automatic Abrasive Supply System

Model | WW-200 |

Power | Non |

Air pressure | 0.4Mpa-0.8Mpa |

Tank | 200kg |

Usage time | 10-12 hours |

1. The abrasive supply system employs a non-electrical structure, requiring no power connection and containing no electrical components. It is suitable for operation in harsh environments such as humid conditions, featuring a maintenance-free and trouble-free design.

2. The pressure tank is constructed from 5mm thick metal plate, effectively bearing greater air pressure, ensuring safety and reliability.

3. The automatic abrasive supply system continuously supplies abrasive to the adjusting abrasive tank on the cutting head via a large supply tank. This automatically supplying tank is rationally designed; a single fill allows for continuous operation for 10-12 hours.

4. A large-diameter drain port at the bottom allows for the removal of foreign objects from the abrasive.

5. Equipped with a safety valve, it automatically releases air and reduces pressure when it becomes too high, ensuring production safety.

If you are interested in any waterjet products, contact us please.