Robotic Waterjet Cutting for EV Automotive Battery Bracket

The reasons why pure electric vehicles (EVS) are popular are mainly as follows:

Environmental protection: Pure electric vehicles do not emit exhaust gas, reduce air pollution and greenhouse gas emissions, and meet the environmental protection requirements of countries around the world.

Fuel cost: Compared with traditional fuel vehicles, the cost of electricity is generally lower, and the charging cost is often lower than the refueling cost, thereby reducing the cost of use.

Government support: Many countries and regions provide financial subsidies, tax incentives and other incentives to promote the purchase and use of electric vehicles.

Technological progress: The continuous advancement of battery technology has improved the range and charging speed of electric vehicles, making them more practical.

Low maintenance cost: The electric motor has a simple structure and relatively few mechanical parts, so the maintenance cost is low and the failure rate is also low

Driving experience: Electric vehicles have smooth power output and rapid acceleration, providing a high-quality driving experience.

Smart technology: Many pure electric vehicles are equipped with advanced driving assistance systems and smart interconnection functions, which attract technology enthusiasts.

Brand image: Manufacturers such as Tesla have created a high-tech and avant-garde image of electric vehicles through market publicity, attracting the attention of consumers.

To sum up, multiple factors such as environmental protection, economy, technological progress and policy support have jointly promoted the popularization and popularity of pure electric vehicles.

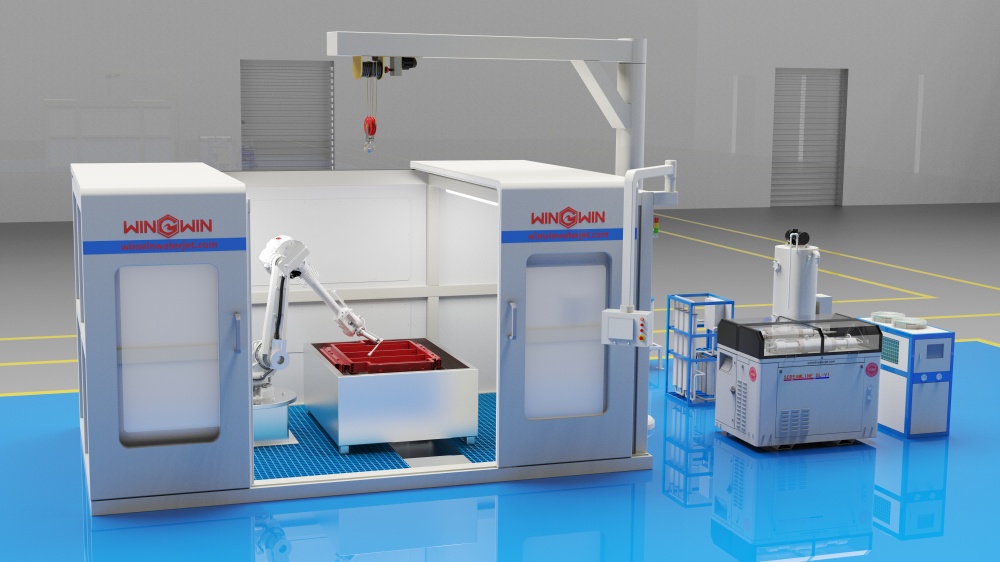

The above robot waterjet cutting workstation is what we provided to the Tesla factory. They are used to cut battery bracket. This is a fully enclosed robot waterjet cutting machine. The fully enclosed type reduces noise pollution, makes the operation safer, and is clean and hygienic.

In addition, it is matched with our SL-VI (50HP) PLUS pump. Its grade, work efficiency and quality are very good. The double intensifier structure can work alternately.

So what materials are the battery brackets of electric vehicles usually made of?

Structural components carry the weight of the battery and provide a strong and safe structure for electric vehicles, and manufacturers use a variety of high-strength materials. These components include the chassis, body panels, and other structural elements that enhance vehicle performance and safety.

So what other parts or materials of the car can be cut by robot waterjet?

Essential Tools and Parts for Electric Vehicle Construction

Electric vehicles consist of various essential components. This article highlights some key structural elements and the tools involved in their engineering.

1. Aluminum housings and covers are vital in electric vehicle construction. Their lightweight nature allows for weight savings while ensuring structural integrity. Additionally, aluminum's superior thermal conductivity aids in effective heat management, which is crucial for the performance of electric vehicle systems. To enhance the engineering process, manufacturers can utilize Kennametal’s PCD tools for machining aluminum or the eBore™ digital fine boring system for precision work on thin walls.

2. Battery housings are critical as they encase the battery, and their safety is paramount. Typically constructed from lightweight materials, these housings shield battery cells from external damage and elements. Many include cooling systems to keep the battery at an optimal temperature. For high-quality manufacturing of these housings, tools like Kennametal’s KOR5DA are ideal for milling aluminum.

3. Carbon Fiber-Reinforced Plastic (CFRP) parts are increasingly utilized in electric vehicles for body panels, hoods, and roof sections. The employment of CFRP tooling can boost energy efficiency and may enhance the vehicle's overall range. Kennametal provides CFRPKenTIP™ FS for modular drilling solutions and inserts.

4. Steel

In the automotive industry, steel is used in a wide range of applications where high strength is required, such as body structures, door locks, body panels and powertrains. There are many types of steel, including stainless steel, high carbon steel, low carbon steel and high strength steel. Waterjet cutting machines are able to process a wide variety of steel for different shapes.

5. Textiles

A variety of textiles are used in vehicle interiors, including carpeting, headliners, seat covers and door linings. Cutting textiles requires a process that doesn't create surface imperfections - after all, aesthetics are a priority. Waterjet technology fulfills this requirement very well. Common automotive textile materials include yarn, nylon fiber, filament and leather.

6. Glass

The automotive industry uses many types of glass and composite materials for windshields, windows and dashboards. Waterjet cutting can process many types of glass, but it cannot cut tempered glass, which breaks on impact.

7. Rubber

Rubber is mainly used for seals, gaskets, tires, and fastening components. The main types of rubber used in these applications are butadiene rubber and styrene-butadiene rubber. All types of rubber can be easily processed with a waterjet cutter.

8. Plastics

Different types of plastics are used for a variety of components in vehicles, such as instrument panels, filter housings, vents, and ducts. These plastics include ABS, PP, SMA, PPE, PC and more. Waterjet technology is able to cut all of these plastics without the use of abrasives.

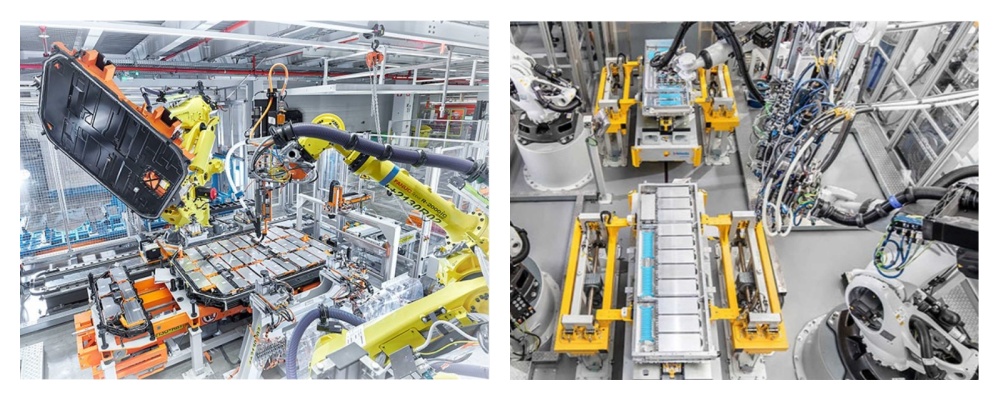

Robot Waterjet Technology in the Automotive Industry

As mentioned above, waterjet technology is highly adaptable in cutting materials. This technology is widely used in the interior and exterior of vehicles due to its versatility. Specific applications include:

Vehicle interiors

When cutting the interior of a vehicle, the main concern is to maintain an aesthetic appearance and ensure that the surface of the material is not damaged. Laser cutting or physical cutting tools generate a lot of heat, which can potentially damage parts. Waterjet cutting, on the other hand, is a cold cutting process that does an excellent job of maintaining the integrity of the material and producing smooth edges. Pure waterjet cutting is often sufficient for these needs. Related parts include:

headliners

floor mats

Dashboards

ventilation grilles

Interior Trim

Dashboard Glass

Exterior

Vehicle exteriors not only need to be aesthetically pleasing, but also require the use of high-strength materials to ensure crash safety. Exterior components are often large in size and more complex than other components. The abrasive waterjet is able to efficiently cut every exterior part, including:

Windshields

Door panels

Body shells

Hoods

Trunk lids

Interior Components

Vehicle interior components are cut with high precision and can be formed into complex cut shapes. 3D waterjet technology is considered to be the second most accurate cutting method after laser cutting, and does not produce the thermal effect that occurs during laser cutting. Therefore, it is widely used for interior components such as:

Chain guards

Brake rotors

Gas pedal brackets

Wing structure inserts

Frame mounting tabs

Canopy Cutout

Brake Pedal Mounting Arm

Contact: Linda Lyu

Phone: +86 15802487169

Tel: +86 15802487169

Email: info@waterjetsupplier.com

Add: Pacific Industrial City 67-32, Shenbei Dist, Shenyang, Liaoning 110001. P. R. China

We chat